The world of racing has long rested on the backbone of robust, durable floatational systems that support endurance, agility, and precision. Yet for millennia, auto racing trailers—designed primarily for hauling vehicles, cargo, or agricultural loads—were often marred by limitations in weight capacity, durability, and performance efficiency. Imagine a vehicle propelled speed and agility while simultaneously enduring the rigors of high-intensity competition, modeling on land but optimized for motion. This ideal has always eluded traditional systems, until the past few years saw a revolution propelled by relentless advancements in materials science, engineering, and digital technology. Innovations are not merely enhancing vehicles; they are redefining the very essence of what auto racing trailer can achieve. From lightweight composites to AI-driven systems, the very foundation of modern auto racing trailers has been transformed, delivering unprecedented speed, responsiveness, and reliability. Today we explore how these innovations are reshaping the landscape, reimagining performance metrics while setting new benchmarks for velocity, efficiency, and adaptability in the racing arena.

The Material Revolution of Auto Racing Trailer: Lightweight Strength in Harmony

At the core of modern auto racing trailer advancements lies a revolution in materials science. Traditional steel rails risked excess weight, compromising both safety and agility, while specialized composites now challenge those assumptions. Carbon fiber-reinforced polymers (CFRPs) and advanced high-strength steels are ubiquitous, offering durabilities that resist both fatigue and acceleration spikes inherent to track conditions. CFRPs, for instance, allow for sleeker designs while maintaining rigidity, reducing stress on frames and enhancing ground effect benefits. Companies like CarbonMatrix and Torca Engineering have pioneered these materials, enabling manufacturers to blend minimalist aesthetics with cutting-edge resilience. The result? Trailers that carry additional weight without sacrificing stability or responsiveness. For example, lightweight yet ultra-dense aluminum alloys are reshaping load distribution, allowing race cars to accelerate funds while maintaining suspension efficiency.

This shift also extends to designs ingeniously tailored for racing environments. Taxonomicely engineered composite tubes replace bulky metal bearings, replacing them with carbon-fiber braces that distribute force more evenly, minimizing wear over time. Moreover, additive manufacturing—3D printing—now integrates precision-engineered parts directly into trailer frames, reducing manufacturing costs without compromising quality. As a result, factory assemblers can now tailor components to specific vehicle or rig, ensuring optimal fitment and performance. The combination of lighter materials and intelligent design has made it possible to augment racing trailers with hidden advantages: greater payload endurance, faster bumper-to-bumper strokes, and reduced thermal expansion during sustained high-speed rides.

Structural Innovations: Engineering Integrity With Agility

The limitations of conventional trailer builds continued to haunt engineers, but today’s structural innovations address these through modular, adaptive frameworks. Modular designs allow for quick customization; for instance, detachable load-distribution modules let teams swap out parts mid-competition to fine-tune weight baling efficiency or suspension damping. Modular aerodynamic housings, now sleek and aerodynamically optimized for specific track conditions, enhance downforce or wind cancellation, crucial in drag racing where trajectory precision is paramount. Furthermore, smart embeddings in composites optimize internal spacing, ensuring optimal airflow while maintaining structural cohesion. The introduction of “adaptive skeletons”—frames engineered to flex efficiently under varying loads—amplifies the trailer’s ability to balance speed and stability. Teams like Mitra Racing have adopted these concepts, embedding flexibility into their chassis so that every kitted segment operates synergistically toward performance goals.

Such structural ingenuity also fosters sustainability efforts, aligning with the growing demand for eco-conscious racing. Lightweight materials reduce energy consumption across the supply chain, while modular designs extend component longevity, minimizing waste. Thus, structurally wise trailers now embody a dual purpose: delivering unparalleled efficiency and adhering to environmental imperatives—a duality that defines the next era of racing fleet design.

Advanced Suspension Systems: Proactive Control in Dynamic Environments

Suspension remains a cornerstone of trailer performance, yet traditional systems often lag behind the demands of high-speed racing. Today, however, cutting-edge suspension systems leverage real-time data and adaptive technologies to mirror the intricate balance required in dinamite hills or grid straights. Active suspension systems equipped with forceVarichem-type actuators or similar responders adjust damping cycles instantaneously, transforming bumps or turns into controlled events rather than disruptions. This capability is pivotal for trailers carrying front-running units that require instantaneous feedback—think of a trailer pivoting to handle abrupt corners or absorbing impacts with nanosecond precision.

Furthermore, the integration of machine learning algorithms allows suspension setups to self-optimize based on track feedback. High-performance trailers now embed sensors that catalog road conditions, tire wear, and payload changes, enabling adaptive tuning protocols. An example is the use of vibration transducers and pressure mapping technologies that refine suspension settings momentarily post-trip, ensuring consistent performance even under variable conditions. Such advancements not only mitigate risks associated with erratic traction but also unlock finer control over vehicle steadiness, making the suspension act as both co-pilot and conductor of the race’s dynamics.

Aerodynamics: Bridging the Gap Between Floorpan and Front Weights

Aerodynamics plays a pivotal role in propulsion—whether through drag reduction or enhanced aerodynamic lift—and its influence on auto racing trailers has evolved dramatically. Modern trailers now incorporate halo-like shields and smoothed profiles that bob smoothly through turns, reducing aerodynamic drag while preserving drainage efficiency. These tailored designs balance airflow management with structural constraints, often employing laminated composites for precision curves on curved surfaces. The result is a blend of streamlined interc oder oversized under-checks that allow excess lateral forces to stabilize the chassis without compromising frame strength.

In drag racing, where minimal drag translates to lap-based superiority, innovations like vented trailer diffusers and aerofoils on load modules are game-changers. These components gently deflect airflow, enabling the trailer to “slip” through corners with less energy expenditure. Electro-hydraulic systems beneath these structures further amplify power transfer, letting teams execute acceleration maneuvers fueled by unmatched efficiency. Thus, the synergy between aerodynamics and structural materials enables trailers to achieve both speed and agility in tandem—a feat once elusive in racing jargon.

Digital Integration: Connectivity at the Tail End of the Acceleration

Emerging digitally, the era of isolated performance metrics has transcended into an interconnected era. Onboard systems now communicate in real time with onboard computers, linking with race software platforms to optimize tracks in stages. Trailer systems equipped with telemetry sensors provide live data to coaches, allowing for pre-race load engineering and in-track adjustments. Machine learning algorithms process this data, predicting optimal speed profiles, x-frame deployment, or even engine timing adjustments to amplify output. Driver teams can even interface directly via mobile or wearable devices, using augmented reality overlays to track tire pressure, fuel flow, or braking points with pinpoint accuracy.

Moreover, blockchain-based supply chain traceability ensures parts remain impeccable through an unreliable global network, directly influencing maintenance schedules and reliability. Sensors embedded in hitch points monitor power consumption or mechanical stress, offering predictive insights that spare teams from costly post-race fixes. These digital threads collectively create a feedback loop where every component optimizes for the race environment, making the entire ecosystem indistinguishable from a unified smart system.

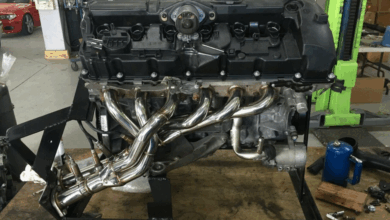

Engine Synergies: Optimizing Power and Efficiency

While engines power the performance, trailers have become key co-stuffers of this synergy. High-performance fuel injection systems paired with lightweight turbochargers deliver sustained power, while precise energy recovery yields traction in adverse conditions. Cutting-edge telemetry feeds allow engine calibration to adapt dynamically to the load—whether accelerating from a stop or softening down in straightaways. Additionally, modular engine mounts permit easy swapping for rapid upgrades, allowing teams to turnover between diesel options for lighter emissions or cylinder head turbines for enhanced thermal efficiency. This interplay extends to the hitch systems themselves, where advanced hydraulic transmission units smoothe power delivery, minimizing lag dips that could pressure ratios.

Looking Ahead: The Future in Motion

The trajectory of auto racing trailer innovation points toward even more radical integration. Imagine augmented reality displays on driver helmets or fully autonomous coordination systems guiding trailers through weather conditions via AI. In the coming decade, road-tested advancements might push toward hybrid systems where materials merge electronic responsiveness—perhaps carbon fiber infused with shape-memory alloys that reshape mid-hairpin turns. Additionally, sustainability mandates could further dictate trade-offs between alexandry materials and environmental impact, with bioengineered polymers or recycled composites entering mainstream use.

Yet obstacles persist: regulatory hurdles for newer technologies, cost barriers for smaller operators, and the sheer complexity of integrating systems seamlessly. Still, these challenges are met with persistent R&D investments and cross-industry collaboration. For now, however, the existential shift—from trailer as passive support to as an active yet harmonious driver of performance—is clear.

A New Paradigm of Performance

Innovation has undeniably transformed racing trailers from versatile workhorses into strategic assets, elevating speed, precision, and resilience to new levels. Each advancement—whether a carbon-fiber rebound in a roof panel, a groove optimized for grip or a sensor array syncing with the hull—contributes to a cumulative effect: a now-era champion in 2010s was pedestrian. Today’s trailers are the blueprints of future competition, defined not just by the weight they move but by the nuances of their adaptation to the constraints and ambitions of the movement itself. As the sport pushes toward lower entry barriers or variable conditions—from off-road fantazzles to ultra-street leagues—the legacy of trailers must evolve, embodying both speed and sustainability in equal measure. In this ongoing dance between necessity and innovation, auto racing trailers stand not merely behind, but ahead, set the standard for what performance implies, and reshaping the trajectory of motorsport for generations to come.